Wood Splitter Plans

Getting ready for winter can be a big chore, especially if you chop your own wood for heat and fireplace esthetics.

A log splitter can make the task a lot quicker and easier. Plus, you can save some serious cash by purchasing and downloading one of our CAD Design Wood Splitter Plans to build a super duty log splitter yourself.

|

Wood / Log Splitter Plans Come In Many Formats And Sizes To Simplify All Your Wood Splitting Needs...

![]() Low

Low Prices!!! - Purchase Log Splitter Design Plans Today!

Low

Low Prices!!! - Purchase Log Splitter Design Plans Today!

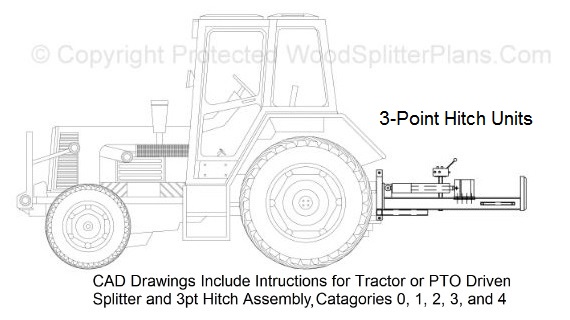

Choices are not just limited to power options. There are gas powered, electric powered, and human powered splitters that offer options with horizontal or vertical trailer hitch units, or 3-point hitch tractor attachment units. Plus other hydraulic or screw type splitting options.

The higher the tonnage rating is on a log splitter, the more horsepower it has to work efficiently on dense hard to split North American Hardwoods like oak, maple, and iron wood like locust or other popular species from your area or territory.

Wood Splitting Options

The most popular power options for log splitters include hydraulic, gas and electric log splitters. Like a manual log splitter, electric log splitters are quiet to operate. Manual Wood Splitters are the most economical choice due to the fact that there are fewer component.

Your power option will also be largely decided by the power source availability. Gas powered splitters can go anywhere, while electric splitters need to be near an electrical power source.

Motorized hydraulic log splitters are suitable for commercial scale log splitting, but they can be more dangerous when not stopped quick if a problem arises.

Horizontal Wood Splitters

Horizontal wood splitters are the most common style and generally include tires along with a tongue to hook to a trailer hitch so you can pull them around from place to place.

They can also be stationary and be set up to run mass amounts of wood through them.

With horizontal wood splitters you simply lay the log down on the track and allow the hydraulic ram to force the splitter head into the log as it splits the log in half. Choose one of our horizontal wood splitter plans.

To use a horizontal log splitter, you pick up the logs and lay them on the log splitter i-beam or tray system for splitting.

Vertical Wood Splitters

Vertical wood splitters utilize the effects of placing a log in the upright position on the splitter with a ram that pushes a spade into the log to split it.

Vertical Wood Splitter Advantages:

Vertical log splitters are sometimes easier to use due to the fact that you don't have to lift the logs up as far to place them on the splitter. A vertical wood splitter requires the logs to be standing up, so rolling the logs into place on the pad which is at ground level can be easier than lifting them into place.

Vertical log splitters also offer a more stable platform when you are going to be working on uneven ground or slopes. Check out our vertical wood splitter plans to see which one will work for your wood splitting needs.

Flywheel

Wood Splitters

Flywheel

Wood Splitters

With a flywheel wood splitter, kinetic energy is stored in the revolving flywheels weight and RPM, offering a tremendous power advantage. Several blows may be made to drive through any type of hard wood grain in order to split the log in half.

With dense hardwood the flywheel may stall on overload impact but can recover in a split second. Check out our flywheel wood splitter page for more information.

While original designs in flywheel splitters used a spade on the actual flywheel to split logs, modern designs offer flywheel energy that powers a ram to force logs into a splitting blade.

Screw

Powered Wood Splitters

Screw

Powered Wood Splitters

Screw type log splitters utilize the concept of screwing a splitter tip that is pointed and tapered back to a wide spade that forces the wood apart as it is screwed into the log.

It is a concept that allows many power options to propel the device. Some innovators have even jacked up a car and attached it to the wheel. Screw wood splitter plans.

Manual

Wood Splitters

Manual

Wood Splitters

Since ancient times when humans mastered the concept of fire they have been splitting wood. Manual log splitters split firewood with ease and safety that hand held wedges, mauls and axes can't match!

These manual firewood splitters operate in a similar manner as the tire jack in the trunk of your car. You create hydraulic pressure by manually cranking a rod to push the ram into a log. This system allows you to split logs with incredible ease and enhanced safety. Manual wood splitter plans.

Sliding-Hammer Manual Wood Splitter

Slide-Hammer

Pounding Force Splits logs easily in seconds with a powerful slide hammer

action. This device replaces axes, wedges and mauls for easier control.

Slide hammer wood splitter

plans.

Slide-Hammer

Pounding Force Splits logs easily in seconds with a powerful slide hammer

action. This device replaces axes, wedges and mauls for easier control.

Slide hammer wood splitter

plans.

Split logs with incredible ease and enhanced safety by placing the wedge tip on a log, then slide the hammer sleeve shaft up and down to split a log in seconds. No more dangerous overhead swinging and broken axe handles, or flying and jammed wedges.

How to Build a Log Splitter

For

many northern homesteaders like myself, splitting logs and creating

firewood can be a necessity when preparing for long cold snowy winter

months. The warmth and comfort obtained from a crackling fire can turn

a cold winter night into a cozy evening with family and friends.

For

many northern homesteaders like myself, splitting logs and creating

firewood can be a necessity when preparing for long cold snowy winter

months. The warmth and comfort obtained from a crackling fire can turn

a cold winter night into a cozy evening with family and friends.

While enjoying the glow of a warm fireplace is a great time to relax, obtaining the split wood you need can be quite a chore without the right tool. Splitting wood can be a tough job with some of the tough, dense north American hardwoods that grow in these territories.

Fortunately, splitting logs can be accomplished without the need for labor intensive ax and maul swinging. Sheer manpower and elbow grease are nice for keeping in shape, but when you have cords of wood to split, a log splitting machine can make light of the situation.

To make life easy, a hydraulic log splitter can do the job, and you can build one yourself if you want to save some cash. Here a some basic steps to building your own hydraulic wood splitter.

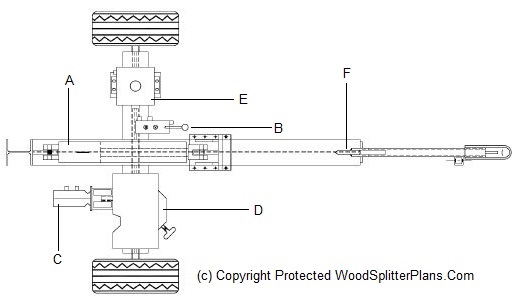

- You can start by sketching out a set of plans, or purchase your log splitter plans here and substitute materials you may have around your yard and shop. Log splitters are basically made with an i-beam frame, engine, splitter head, hydraulic cylinder, oil pump along with a valve system and hoses.

- Assemble a wheeled metal trailer type structure by attaching a axel to the I-beam and a tongue on the front to pull it around. This will be the main structure to assemble your log splitter on. This allows you to tow your log splitter around to remote job sites or closer to your pile of wood you need to split.

- Attach an electric or gas powered motor to a 2-stage hydraulic oil pump that can pump 3 gallons per minute at 2500 PSI.

- Attach a hydraulic valve to the hydraulic cylinder and oil tank. The typical hydraulic cylinder is two to three feet long and has a diameter of 4 inches.

- Connect a hydraulic hose to the valve and the oil pump. When the pump is active, high-pressure oil will go to the valve. The valve is then used to control the hydraulic cylinder's movement and the splitting wedge travel. The pressure of the moving oil will drive a piston in the hydraulic cylinder to push the rod out and force the log into the wedge to be split.

- You will need to securely attach hoses to the fittings on the top of a hydraulic oil tank. Hydraulic oil can be drawn from the tank and through the hose to feed the hydraulic pump and cylinder as needed. A oil filter should also be plumbed in to filter the oil.

- Weld together a V-shaped log tray on the frame that can hold logs in place for splitting. It's best to arrange the pieces so that the hydraulic cylinder rod travels over them when activated.

- Attach the push plate if building a horizontal splitter to the hydraulic cylinder and splitting head to the end of the beam. The wedge can be attached to the cylinder rod as well but you will run into issues with the log getting stuck on the wedge and drawn back at times when is is not fully split. Depending on which mounting location your chose, the other end needs a stopper plate for the log to rest against or, a pusher plate for the cylinder to push the log with.

- That's the basics to a log splitter but always remember these mechanical devices can be dangerous so be careful out there!

Typical Tools Needed To Build a Wood Splitter

- 220 Volt heavy duty welder

- Cutting Torch

- Wrenches, Grinder, and other common shop tools...

Website Policies: Digital Goods and Refunds

Digital Goods: Digital Goods may include background watermark images or text such as our trademark domain name.

Digital Goods Delivery: After purchase you are redirected to the download page, and a download link is also sent to your email address registered with PayPal.

Refunds: Due to the fact that we have no control over the deletion of digital files from your device, Download Purchases for Digital Goods are Not Refundable.

We do NOT harvest, sell, or distribute purchaser data. Keep your purchase emails for reference as proof of purchase for support. Your receipt/invoice comes from PayPal.

To combat fraud, we have a system in place that records purchasers IP Address and download details. Fraudsters and scammer details will be reported to PayPal.