Manual Wood Splitter Plans

Since

ancient times when humans mastered the concept of fire they have been

splitting wood. Splitting logs by hand with an axe or mall can be a

tremendously exhaustive process, as well as time-consuming and possibly

dangerous.

Since

ancient times when humans mastered the concept of fire they have been

splitting wood. Splitting logs by hand with an axe or mall can be a

tremendously exhaustive process, as well as time-consuming and possibly

dangerous.

To save some time and effort, instead of using an axe or maul to split a high quantity of wood, consider using a manually operated hydraulic log splitter to reduce the time and risk. Manual log splitters have the ability to split lots of firewood with ease and safety that wedges, mauls and axes simply can't compare to!

Manual wood splitters operate largely in a similar way that the tire jack from the trunk of your car operates. You create hydraulic pressure by manually cranking a rod to increase hydraulic fluid pressure that pushes a ram with a wedge tip into a piece of wood or log to split it.

|

Manual log Splitter

How To Build A Manual Log Splitter

Powered log splitters are highly effective for splitting large quantities, but they can be fairly expensive. Unlike powered wood splitters that operate by using a hydraulic or mechanical pump to apply the pressure, manual log splitters require human effort to pump the levers that force a hydraulic ram into a log.

Manual log splitters can be designed to operate by hand, or by foot. Most operators find that the foot-powered wood splitters are much easier to use since the legs have more power and it frees up the hands to hold and guide the logs as needed in the splitter.

Manual wood splitters can be built at home with easy to get parts and a few industrial tools like a welder and torch. As with any machinery, it is imperative that proper precautions be taken in order to avoid injury when building and operating a manual log splitter.

A manual-powered hydraulic wood splitter is relatively cheap to build and can save hours of time, and save you from painful back and shoulder injuries.

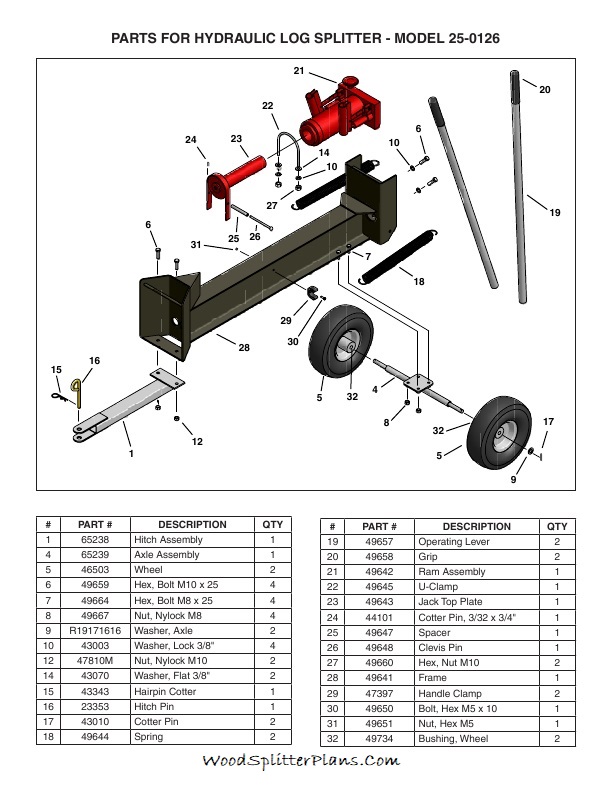

Manual Wood Splitter Parts

Basic Hydraulic Wood Splitter Construction

Step 1 - Collect The Materials Needed

To build a log splitter with a hydraulic pumping system, you will need the following materials:

- An adequately-sized hydraulic cylinder

- A 5-gallon hydraulic tank

- Hydraulic Control valve

- Hydraulic Hoses

- Steel blades 10 inches long, ¼-inch thick and 4 inches wide (4)

- Steel pipe about 20 inches long and 2 inches thick to support the spade

- Steel support and wedge system for the base structure of the splitter

Step 2 - Construct the Spade Blade System

Begin by welding the 4 blades together in a criss-cross shape. You may find it helpful to bevel the inner corners of the blades to make it easier to weld them together. Begin by welding 2 of the blades together at a 90 degree angle. Repeat this step with the other 2 blades, then weld the 2 pairs of blades together into the cross pattern.

Prepare the 20 inch steel pipe by cutting notches on one end to match up with the 4 blades. Weld the blades into the pipe securely with reinforcement or filler rod to insure it is a strong structure.

Step 3 - Set Up Your Hydraulic Pump, Tank and Hoses

Local home improvement centers like Home Depot carry the basic hydraulic pump systems needed. A working pressure of about 1500 psi should be adequate for the average wood splitter. Use the instructions given by the manufacturer to set up the hydraulic pump system properly.

Step 4 - Attach the Spade Blade System to the Pump

Ensure that the pump is deactivated and fit the blade system to the assembled hydraulic pump. After the blade system is attached securely, test the log splitter with a log and make any adjustments to the blades or pump that may be necessary for proper operation.

Consult your local home improvement specialist for further advice if you have any questions or concerns about your log splitter!