How A Hydraulic Wood Splitter Works

How Hydraulic Log Splitters Work

One of the most common examples of simple hydraulic devices that are used today to simplify the workload of normally exhausting projects, is the wood splitter.

In its construction you will find all the basic components required

to run a hydraulic machine. These main components work with the frame

system and include:

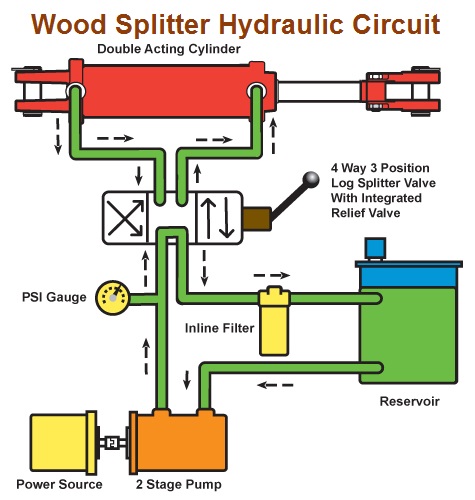

- Hydraulic fluid tank and hoses

- Hydraulic pump

- Hydraulic cylinder or ram

- Hydraulic control valve

- Wood splitter head or blade

- Motor or power source

- Splitting Wedge

In the construction of a wood splitter you will find that the main frame or I-beam is the solid part of the structure that everything else is built around. From there wheels and an axel are added if it is intended to be portable. If this is the case then generally a tongue and coupler for towing is included.

|

Hydraulic Power Source

A wood splitter power source is determined by preference, whether it be electric, PTO, or a gas powered engine. Most often you will see a small four-stroke gasoline engine in these cases that provides the power for the log splitter system. The size of the motor is calculated to work with the hydraulic cylinder and pump. You need to consider where, how and for what purpose it will be used to see how the power source chosen matches up to your intended use, Electric is not good out in the middle of the woods!

The Engine is Attached to a Hydraulic Oil Pump

The hydraulic oil pump in combination with the motor creates a stream of high-pressure oil that runs through the control valve for easy hands on operation. The operator pulls or pushes a lever on the valve to activate the hydraulic cylinder to split a log and return to the starting position. A hydraulic oil tank is attached to the system that feeds the pump and it generally includes a filter to keep the oil clean.

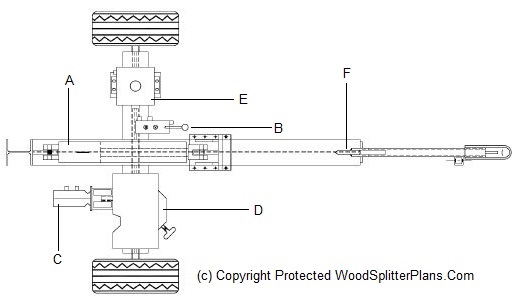

Main Wood Splitter Components

A. Hydraulic Cylinder B. Hydraulic Valve C. Hydraulic Pump D. Power Source, Motor E. Hydraulic Oil Tank F. Splitting Wedge

See more about these components on our wood splitter components page.

A two-stage pump contains two sections and an internal pressure-sensing valve that cuts over between the two pumping sections. One pump section generates the maximum gallons per minute (GPM) flow rate at a lower pressure. This is used, for example, to pull the splitting wedge back out of a log after the wood has been split. This is good because drawing the piston back into the cylinder takes very little force and can happen quickly to save time. This is accomplished with the higher flow rate on the low pressure stage.

However, when pushing the wedge into a log, you want the highest pressure possible in order to generate maximum force for splitting hard or dense wood. The "high pressure, lower volume" flow rate generates more power in this stage and speed is not a big concern, so the pump switches to this stage to ensure there is enough force to split the log.