Flywheel Wood Splitters

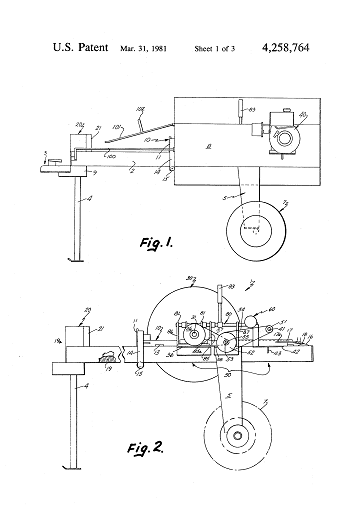

With original designed flywheel wood splitters, kinetic energy is stored in the revolving flywheels weight and RPM, offering a tremendous power advantage. Several blows may be made to drive through any type of hard wood grain in order to split the log. With dense hardwood the flywheel may stall on overload impact but can recover in a split second.

Modern

Flywheel Splitters work differently. Kinetic energy is stored in revolving

wood splitters flywheels. These flywheels are firmly secured to a one-piece

pinion gear. To transmit power from the pinion gear to a log, a rack

gear is engaged by a cam-lock method. The rack gear, now fully engaged

and locked in the pinion gear, moves out with a 12 to 24 ton force.

Modern

Flywheel Splitters work differently. Kinetic energy is stored in revolving

wood splitters flywheels. These flywheels are firmly secured to a one-piece

pinion gear. To transmit power from the pinion gear to a log, a rack

gear is engaged by a cam-lock method. The rack gear, now fully engaged

and locked in the pinion gear, moves out with a 12 to 24 ton force.

Because of the flywheel weight and RPM, being mounted on ball bearings and secured to the frame, the pinion gear has a tremendous power advantage. At the end of the full 24" stroke, the rack being spring loaded upward and backward disengages the cam lock and immediately returns to start position.

|

Flywheel Wood Splitter Power Principals

Flywheel

wood splitter designs offer many patented forms for driving a ram into

a piece of wood to split it onto separate pieces.

Flywheel

wood splitter designs offer many patented forms for driving a ram into

a piece of wood to split it onto separate pieces.

With a flywheel operation this log splitter action can be instantly triggered to engage or disengage the momentum of a motor driven flywheel.

This in turn triggers the drive train operation including a clutch that transfers the flywheel energy when called upon to propel the ram into a piece of wood to split it in a quick stroke compared to conventional hydraulic operated ram splitters.

Safety features allow the resistance to effectively disengage the motor if the flywheel load becomes intense enough to cause a motor overload.

This rack and pinion driven ram system offers a much faster cycle time than what is encountered with conventional log splitters.

Super Split Flywheel Wood Splitter

The SUPER SPLIT® log splitter is a semi-automatic machine designed with safety in mind. Because of this safety feature, every cycle must be manually activated. However, after activation it will complete a full cycle and return to the starting position. The rack, however, can be disengaged at any time by tapping down on the operating handle.

With super dense woods, the flywheel may stall on overload. Flywheel recovery time is about 1/2 second and several blows may be made to drive through any type of hard wood. If you have ever swung a heavy maul to land a big blow on a log, you can easily see why the SUPER SPLIT® wood splitter principle offers a more efficient system for splitting wood.

Modern flywheel log splitters produce more firewood in less time!

Vintage Flywheel Wood Splitter Designs

Vintage Pyramid Flywheel Wood Splitters

Vintage Belt Driven Wood Splitter